The Importance of Aluminum Foundry in Advancing Industrial Manufacturing Techniques

The Aluminum Foundry plays an essential role in the advancement of commercial production techniques. Its lightweight residential or commercial properties and convenience make Aluminum an optimal selection for various applications. Advanced casting methods, consisting of die casting and 3D printing, permit detailed designs and automation. As the market moves towards automation and sustainability, concerns emerge concerning the future trajectory of Aluminum foundries and their influence on manufacturing efficiency. What obstacles and advancements exist ahead?

The Role of Aluminum in Modern Manufacturing

Aluminum plays a critical role in contemporary production as a result of its unique residential properties and convenience. As a lightweight steel, it significantly reduces the overall weight of items, enhancing fuel efficiency in transport and aerospace sectors. Its exceptional deterioration resistance warranties durability and integrity, making it perfect for different applications, from vehicle parts to developing products. Light weight aluminum's pliability permits it to be quickly shaped into intricate layouts, assisting in innovative item advancement. Its conductivity makes it appropriate for electrical applications, adding to advancements in electronic devices and eco-friendly energy technologies. The adaptability of Aluminum likewise includes its recyclability, which adds to sustainable production methods. As sectors continue to focus on efficiency and ecological responsibility, Aluminum remains an essential product, fostering development and boosting manufacturing processes across multiple markets. Its role is not simply functional; it is foundational to the evolution of modern commercial methods.

Key Benefits of Aluminum Casting

The advantages of Aluminum casting are substantial, adding to its appeal in various commercial applications. One crucial advantage is the lightweight nature of light weight aluminum, which reduces transport expenses and improves fuel efficiency in automobile and aerospace markets. Furthermore, aluminum's superb rust resistance extends the lifespan of cast parts, making them excellent for outside and marine settings.

Additionally, Aluminum casting permits complex geometries and complex designs, giving makers with better adaptability in product development - Wisconsin Aluminum Foundry. The product additionally exhibits great thermal and electric conductivity, making it suitable for a variety of digital applications

An additional advantage is the quick solidification process, which brings about finer microstructures and improved mechanical properties. In addition, Aluminum can be recycled repetitively without losing its fundamental top qualities, advertising sustainability in producing techniques. These advantages highlight Aluminum spreading's pivotal duty ahead of time commercial production techniques while fulfilling varied engineering demands.

Innovative Casting Techniques and Technologies

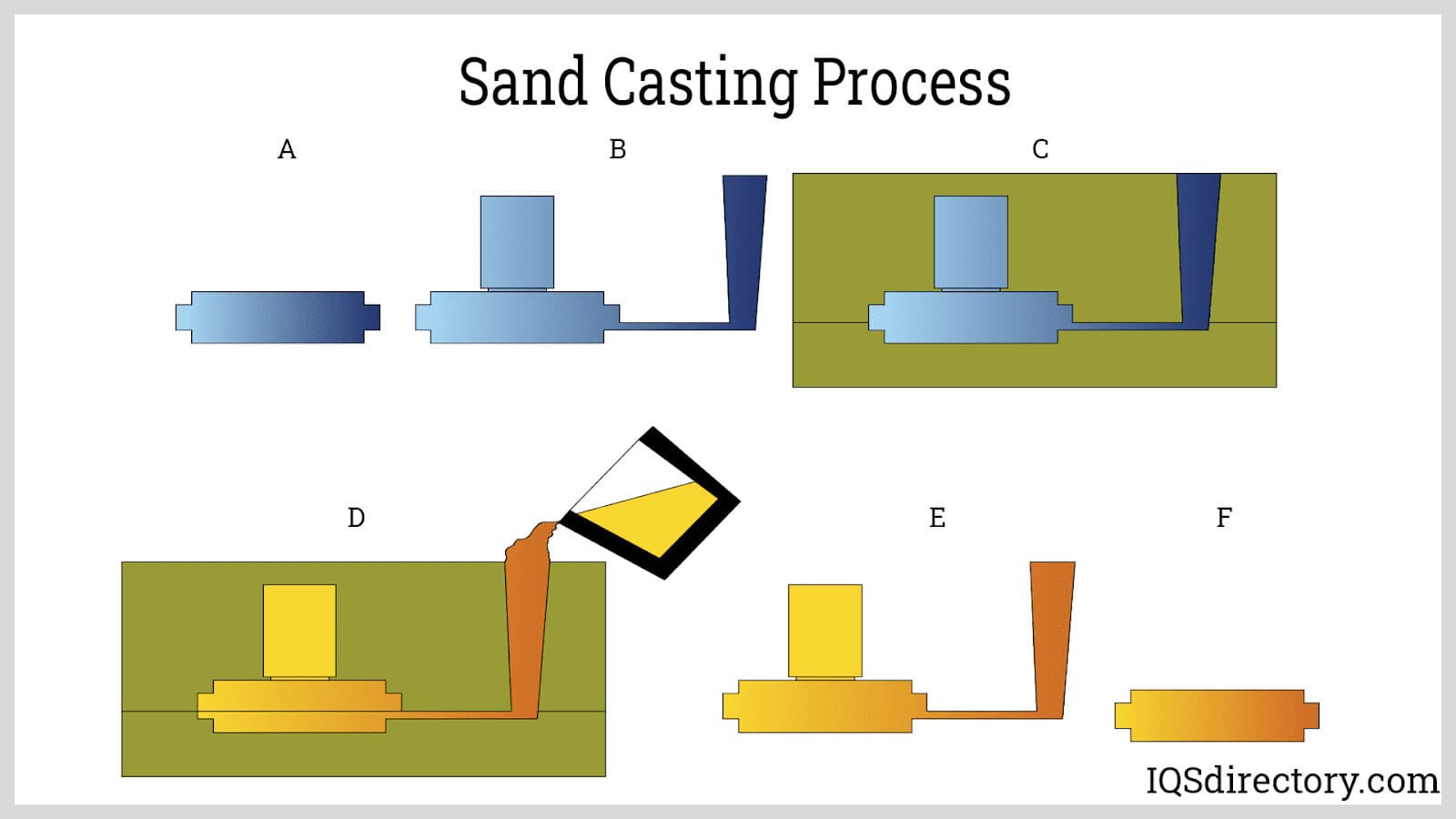

Various innovative spreading methods and technologies have actually arised to enhance the effectiveness and top quality of Aluminum production. Amongst these, die casting sticks out as a method that enables high-volume manufacturing of intricate forms with excellent dimensional accuracy. This technique makes use of high pressure to inject molten Aluminum right into a mold, leading to smooth surfaces and reduced requirement for machining.

Another significant innovation is making use of 3D printing for mold and mildews, which makes it possible for fast prototyping and decreases lead times significantly. This technology permits detailed designs that conventional approaches may struggle to attain.

Additionally, financial investment spreading continues to develop, using advanced products and processes to create precision parts. The adoption of computer system simulations in the spreading procedure has actually better enhanced end results by anticipating possible problems and maximizing mold and mildew layouts. With each other, these developments are changing Aluminum factories, leading the way for much more efficient manufacturing and exceptional item high quality in numerous industries.

Ecological Effect and Sustainability in Aluminum Foundries

As sectors significantly prioritize sustainability, the environmental effect of Aluminum shops has actually come under scrutiny. These facilities are considerable factors to greenhouse gas emissions and energy consumption, mainly as a result of the energy-intensive procedures associated with melting and spreading aluminum. The extraction of bauxite, the main ore, further intensifies environmental issues, causing habitat devastation and pollution.

In feedback to these challenges, many Aluminum shops are adopting more lasting methods (Metal Castings). Technologies such as reusing scrap Aluminum considerably minimize power use and emissions, as recycling requires just a fraction of the energy needed for key manufacturing. Furthermore, the assimilation of eco-friendly power sources, such as solar and wind power, is obtaining grip in shops aiming to decrease their carbon impact

Furthermore, advancements in modern technologies that reduce waste and improve resource performance are becoming important for the future of the Aluminum market. These efforts underscore the change towards a much more ecologically accountable and lasting approach in Aluminum factories.

Applications of Aluminum Spreading Throughout Industries

Aluminum spreading finds widespread application across varied industries, owing to its favorable homes such as light-weight, corrosion resistance, and outstanding machinability. In the vehicle industry, suppliers make use of Aluminum castings for engine elements, transmission housings, and architectural parts, improving gas efficiency and efficiency. The aerospace market take advantage of light weight aluminum's strength-to-weight ratio, using it in airplane frameworks and parts, which add to minimized total weight and boosted fuel economic situation.

The consumer electronic devices useful link field uses Aluminum spreadings for real estates and framework, integrating aesthetic appeal with durability. In construction, Aluminum castings are employed for home window frames, doors, and architectural aspects, supplying both functionality and design versatility. Furthermore, the aquatic industry utilizes Aluminum casting for boat hulls and installations, making certain resistance to saltwater rust. This convenience throughout numerous fields emphasizes Aluminum spreading's critical function in contemporary industrial applications, driving advancement and efficiency.

Challenges Encountered by Aluminum Foundries

Aluminum shops come across substantial obstacles in conference stringent environmental laws while maintaining operational performance. Furthermore, a scarcity of experienced labor intensifies these difficulties, impeding productivity and technology. Resolving these problems is necessary for the sustainability and development of the Aluminum casting market.

Ecological Rules Compliance

Although Aluminum foundries play an essential duty in industrial production, they commonly encounter substantial difficulties in adhering to ecological regulations. These policies are made to reduce air and water pollution, waste generation, and power consumption. Foundries typically need to purchase innovative modern technologies to satisfy rigid discharge criteria and take care of harmful materials effectively. The costs associated with these upgrades can strain funds, specifically for smaller procedures. Furthermore, the complexity of passing through governing structures can bring about conformity errors, leading to costly charges. Moreover, continual adjustments in guidelines call for foundries to adjust swiftly, often demanding recurring training and updates in operational techniques. Stabilizing governing compliance with production effectiveness continues to be a critical problem for the Aluminum Foundry sector.

Competent Labor Shortage

As the Aluminum Foundry industry remains to develop, a pushing challenge has actually arised: an experienced labor shortage that intimidates the field's efficiency and growth. This scarcity is mainly sustained by an aging workforce and the absence of passion among more youthful generations in seeking professions in manufacturing. Several knowledgeable tasks need specific training and experience, which are progressively hard to find. Subsequently, Aluminum shops struggle to keep operational effectiveness, leading to hold-ups and raised manufacturing costs. Efforts to attract brand-new ability through instruction programs and collaborations with schools are underway, yet these efforts require time to yield outcomes. Without a durable influx of knowledgeable workers, the Aluminum Foundry industry Related Site may face substantial challenges in fulfilling the demands of modern-day commercial manufacturing.

Future Patterns in Aluminum Foundry Production Techniques

The future of Aluminum Foundry manufacturing strategies is poised to be substantially formed by improvements in automation and lasting product technologies. Automation is anticipated to boost efficiency and accuracy in Foundry procedures, lowering labor costs and minimizing human error (Aluminum Foundry). Meanwhile, a growing focus on sustainability will certainly drive the development of environment-friendly materials and methods, straightening the market with global ecological goals

Automation in Foundry Processes

Lasting Product Innovations

While the Aluminum Foundry market embraces automation, an identical focus on sustainable material advancements is improving production techniques for the future. Innovations in recycling processes are making it possible for factories to utilize post-consumer aluminum, significantly decreasing power consumption and waste. The advancement of eco-friendly additives and layers is decreasing the ecological impact associated with standard products. Developments in light-weight Aluminum alloys are boosting performance while advertising sustainability, making items not just extra reliable but also simpler to reuse at the end of their life cycle. As the industry adapts to more stringent environmental regulations, these pop over to this web-site sustainable practices are becoming essential. Eventually, the commitment to lasting material advancements in Aluminum factories will drive enhanced performance while addressing worldwide ecological challenges.

Frequently Asked Concerns

Exactly How Does Aluminum Compare to Various Other Steels in Casting?

Aluminum supplies advantages over other steels in casting, consisting of lower melting factors, exceptional fluidness, and resistance to deterioration. These buildings enable complex layouts and faster manufacturing, making Aluminum a recommended option for many industries.

What Security Procedures Remain In Area in Aluminum Foundries?

Safety and security procedures in Aluminum foundries include safety equipment for employees, correct air flow systems, routine tools maintenance, fire avoidance methods, and rigorous adherence to safety and security regulations, making sure a safe and secure environment while reducing the risk of injuries and mishaps.

Just How Are Aluminum Alloys Selected for Certain Applications?

Aluminum alloys are chosen based upon mechanical properties, corrosion resistance, and thermal conductivity. Designers review application needs, considering aspects like weight, strength, and environmental problems, making certain perfect performance for particular industrial or industrial usages.

What Is the Average Life Expectancy of Aluminum Cast Products?

The average lifespan of Aluminum cast items commonly varies from 20 to 50 years, depending upon ecological aspects, usage problems, and maintenance practices. Appropriate treatment can substantially expand their useful longevity and performance effectiveness.

Exist Certifications for Aluminum Foundry Processes?

Yes, there are accreditations for Aluminum Foundry processes, including ISO 9001 for top quality administration systems and particular industry criteria like ASTM and SAE, which guarantee adherence to quality and safety in Aluminum manufacturing and casting.

Aluminum factories play a vital duty in commercial production, they often deal with considerable obstacles in complying with environmental regulations. Aluminum factories battle to keep functional performance, leading to delays and raised manufacturing costs. The future of Aluminum Foundry manufacturing methods is poised to be substantially formed by improvements in automation and lasting product innovations. Increasingly, automation is forming the landscape of Aluminum Foundry production methods, driving effectiveness and accuracy. While the Aluminum Foundry industry accepts automation, a parallel focus on sustainable product innovations is reshaping production techniques for the future.